Greubel Forsey Hand Made 1, which is the result of 6,000-hour labor, relocates Swiss watchmaking from industrial production to the ‘hands’ of traditional watchmaking.

Before the Industrial Revolution and the development of mass production, different specific features, tools, and man-controlled machines were required to manufacture the components of a watch. Along with industrialization, artisanship in many areas has also vanished. Robert Greubel and Stephan Forsey, on the other hand, used both prototypes and spare parts for restoration during their education and business life to enhance their artisanship experience.

Robert Greubel and Stephan Forsey took the first step of a long journey by launching the Naissance d’une Montre 1 project with the Time Æon Foundation to transfer such rich and irreplaceable skills to future generations, which is the core of the watchmaking heritage.

Hand Made 1 is a watch that displays hours, minutes, seconds along with a tourbillon. The production process of the watch has been very educational and unexpected for everyone because it is not possible to manually copy an existing mechanism. Therefore, Hand Made 1 was created from nothing. Traditional finishing and hand finishing experts have paid their full attention to the creation of 272 movement components and 36 case parts using old techniques.

To find new technical solutions to the problems encountered with this project, talents such as creativity and inventiveness had to be put forward. Redesigning some movement parts to simplify and increase the number of components to make some mechanisms manually, such as the tourbillon, made the process even more difficult. The size of the watch, which is relatively modest at 43.5mm in diameter and 13.5mm in height, has further increased the level of difficulty.

According to the Greubel Forsey criteria, more than 800 different parts had to be manufactured to produce the 308 components of Hand Made 1. It took almost 35 times longer to build the entire Tourbillon cage compared to a standard ‘high-end’ tourbillon. 8 hours and 12 separate processes for manufacturing the smallest screw on a turning lathe; the production of a handmade wheel of Hand Made 1 lasted 600 times longer than that of a high standard wheel.

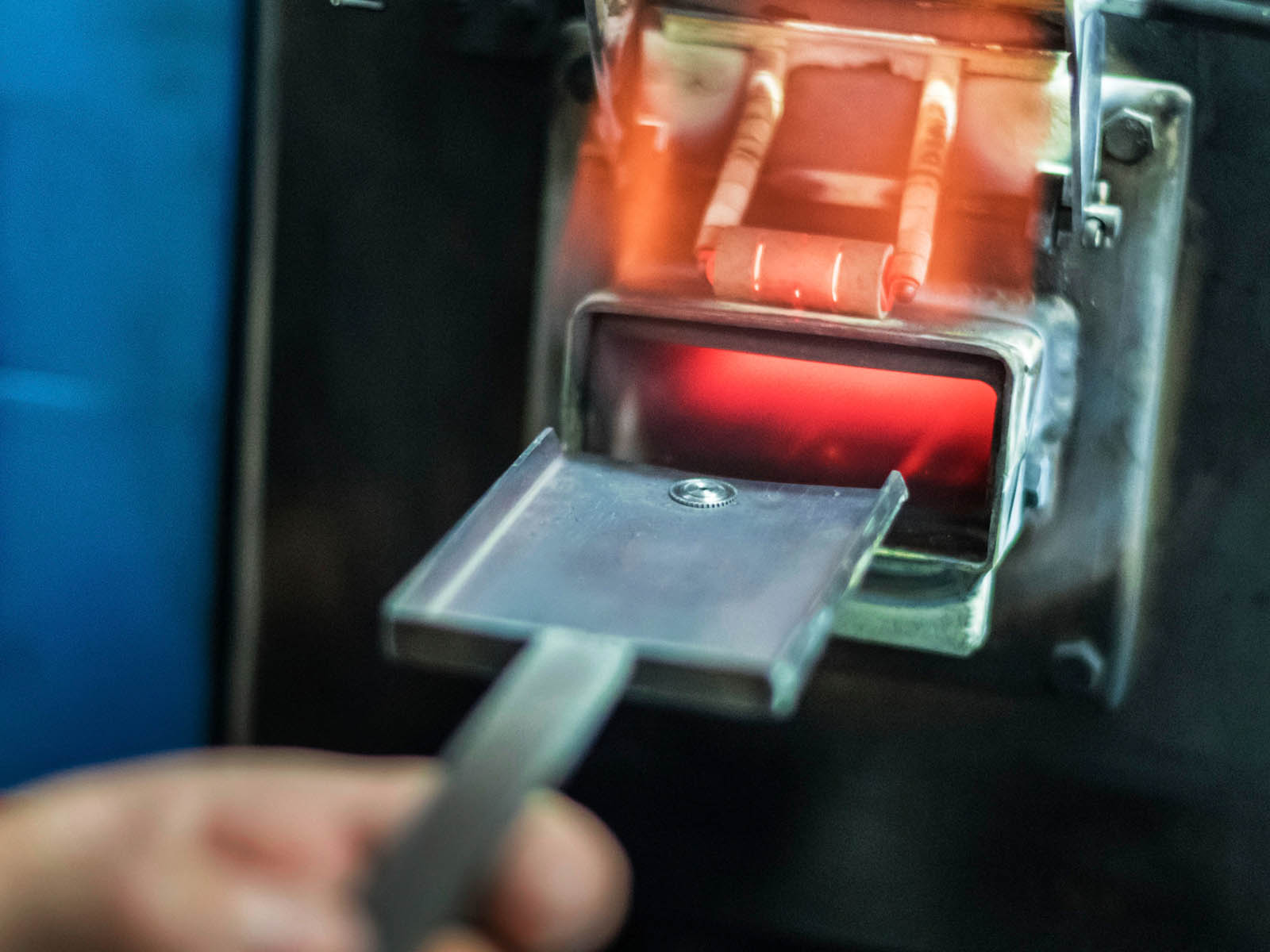

Each Greubel Forsey Hand Made 1 is unique. The journey of the timepiece begins with the regulating organ. Let us add that the components that make up the regulatory body, including the balance spring, are produced by hand in Greubel Forsey workshops. The produced spring is hand-wrapped in the rolling mill without the help of a computer, which is now forgotten and only a few can be done at a time. The balance wheel, which is manufactured with great care, is also produced completely by hand. The production of the escapement wheel with 20 teeth means another challenge for the brand. It takes about a month and a half to get a single sweat arm ready.

The handmade tourbillon cage has 69 components and has a total weight of 0.521g. The challenge is that it is much harder to capture the geometric symmetry of the CNC machine with a conventional precision drill. For this reason, the brand had to increase the number of components to make this elegant movement. The caliber parts; bridges, polished inner and outer vertical wings, ‘Gratté’ main plate and polished wheels are all handmade.

Hand Made 1’s open dial stands out with its elaborately shaped flame blue steel hands and enameled handmade ring.

The model, which comes in an 18K white gold case that is also hand-made, will be offered one or two pieces per year and will bear the Hand Made sign at 6 o’clock instead of Swiss Made.