One of the important facts that we love about luxury watchmaking is ‘traditionalism.’ Therefore, we do not forget the important dates and celebrate anniversaries with great enthusiasm. However, there are some innovations that were introduced not long ago, which have been able to provide enormous benefits without compromising the basics of tradition.

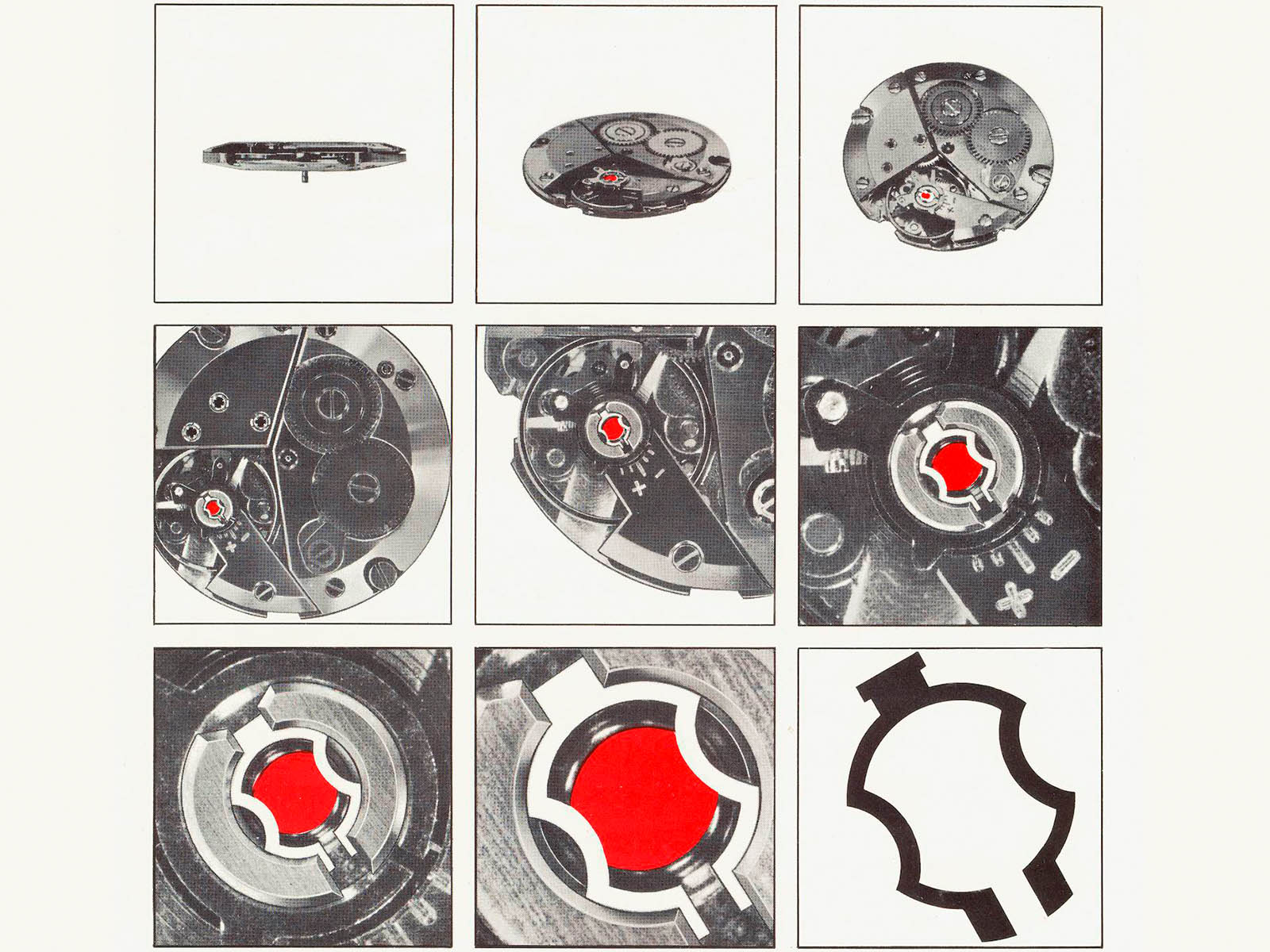

Incabloc Shock Protection System

Imagine that the watch that you treat with kid gloves fell from your hand. You heave a sigh of relief when you pick it up and see it’s still working. What gives you this relief is the shock protection systems. Developed by two Swiss engineers, Georges Braunschweig and Fritz Marti in 1934, the ‘Incabloc Shock Protection’ system protects many watches today. The Incabloc system utilizes a bow that is similar to the lyre instrument. This spring displaces the precision bearings during the impact to soften the contact with the metal housing. In this way, the energy created by the impact is largely damped before reaching the bearings. When the impact ends, the springs allow the parts to return to their places. In addition to many ETA movements, many of the most important brands of luxury watchmaking such as A. Lange & Söhne, Glashütte Original, and Patek Philippe benefit from Incabloc Shock Protection.

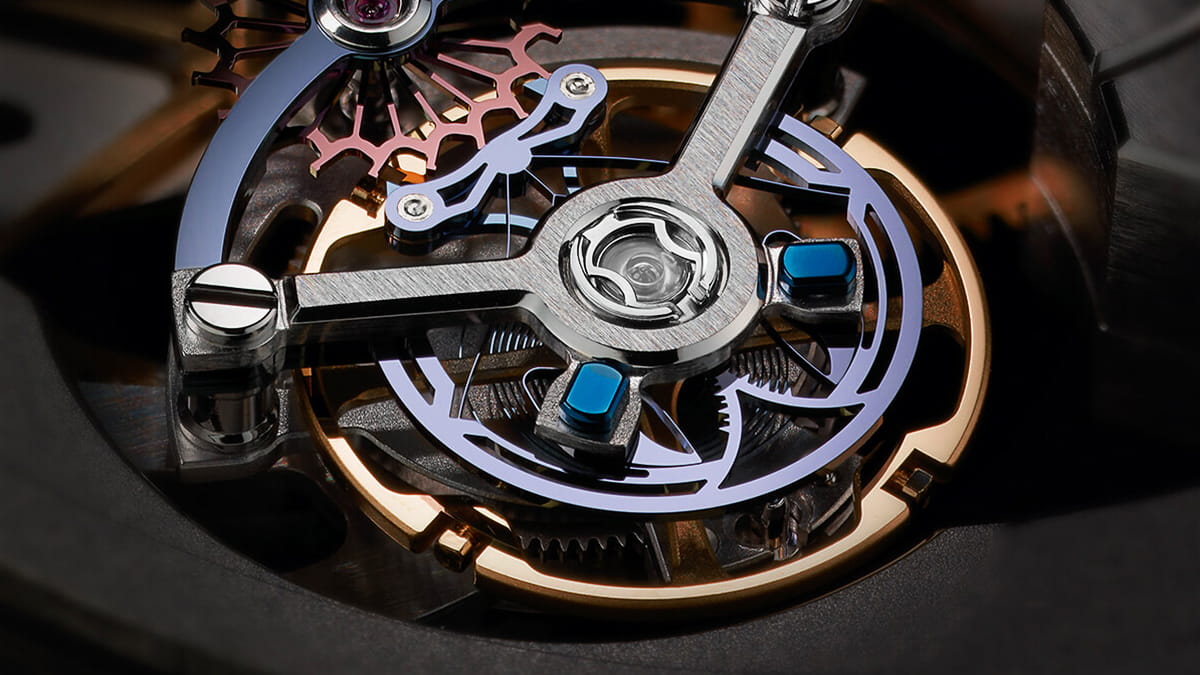

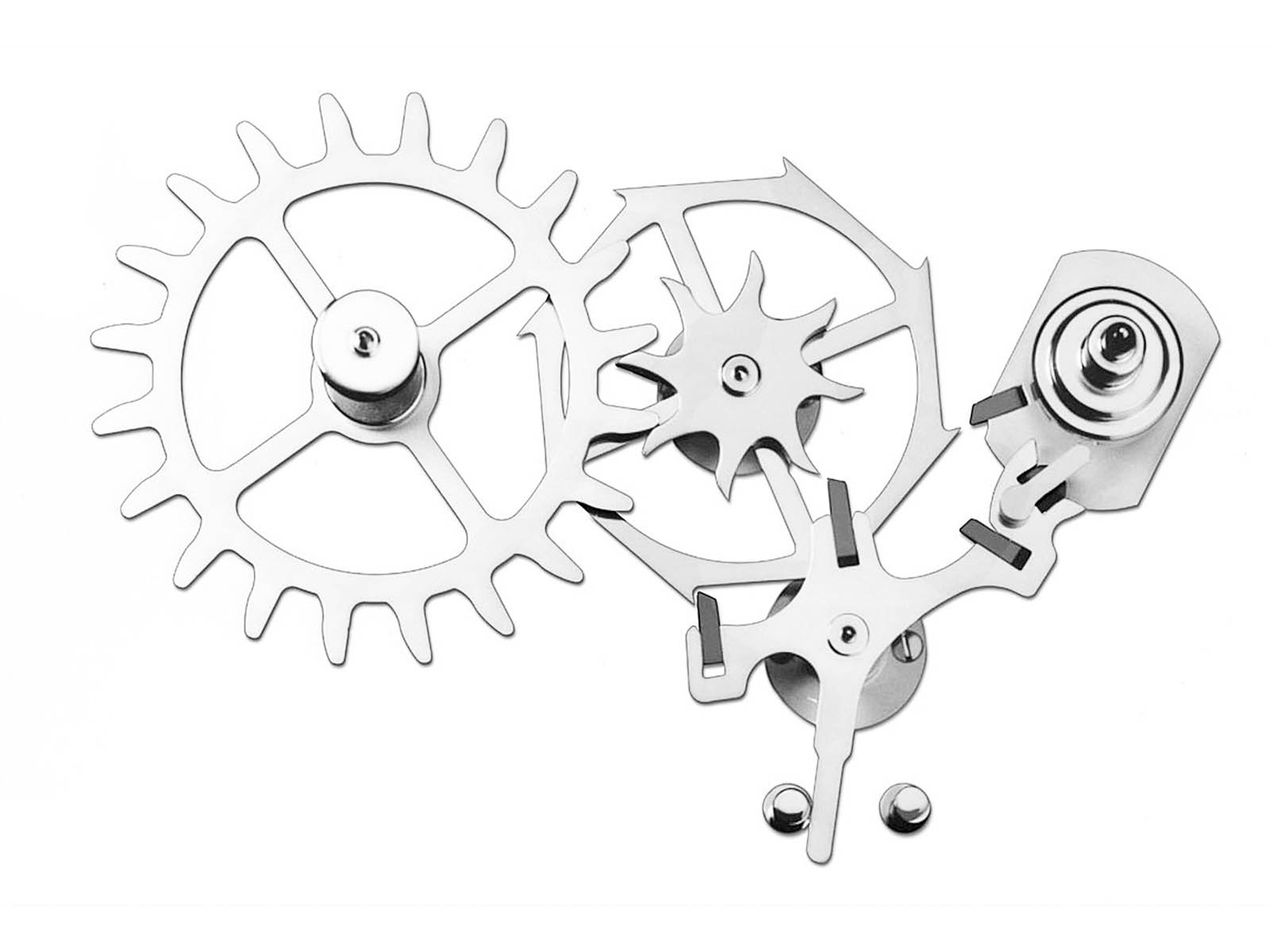

Co-Axial Escapement

The Co-Axial Escapement, brought to the watchmaking industry by the British watchmaker George Daniels, emerged when American industrialist and watch collector Seth G. Atwood wanted an innovation that would fundamentally improve the performance of mechanical watches. In response, George Daniels developed the Co-Axial escapement in 1974 and patented it in 1980. The escapement eliminates friction, providing greater precision in timekeeping and extending service time. Although George Daniels shared his invention with many brands, he only got positive feedback from Omega. Since 1999, the Co-Axial escapement has been used in many movements such as the Caliber 2500, chronograph movement family Caliber 3313, Caliber 8500 introduced in 2007 and 8520/8521. Like defying the luxury watchmaking industry’s idea of “for limited editions only”, the brand continues to use Co-Axial escapements in almost all mechanical models.

Silicone Parts

The use of silicone parts in the production of luxury watches is becoming increasingly common. However, there was this one brand that made the first introduction. Ulysse Nardin’s Freak Vision, which was released in 2001, had a mechanism called ‘Dual Direct Escapement’, which was made of silicon, featuring crucial components for a movement. Two years later, a silicon balance spring was used in Sonata and, InnoVision was introduced in 2007 offering many innovations in line with its name. You might think that the use of silicone is a little overrated, but Ulysse Nardin gave us the best lesson on how a material can be used for different tasks in the right hands.

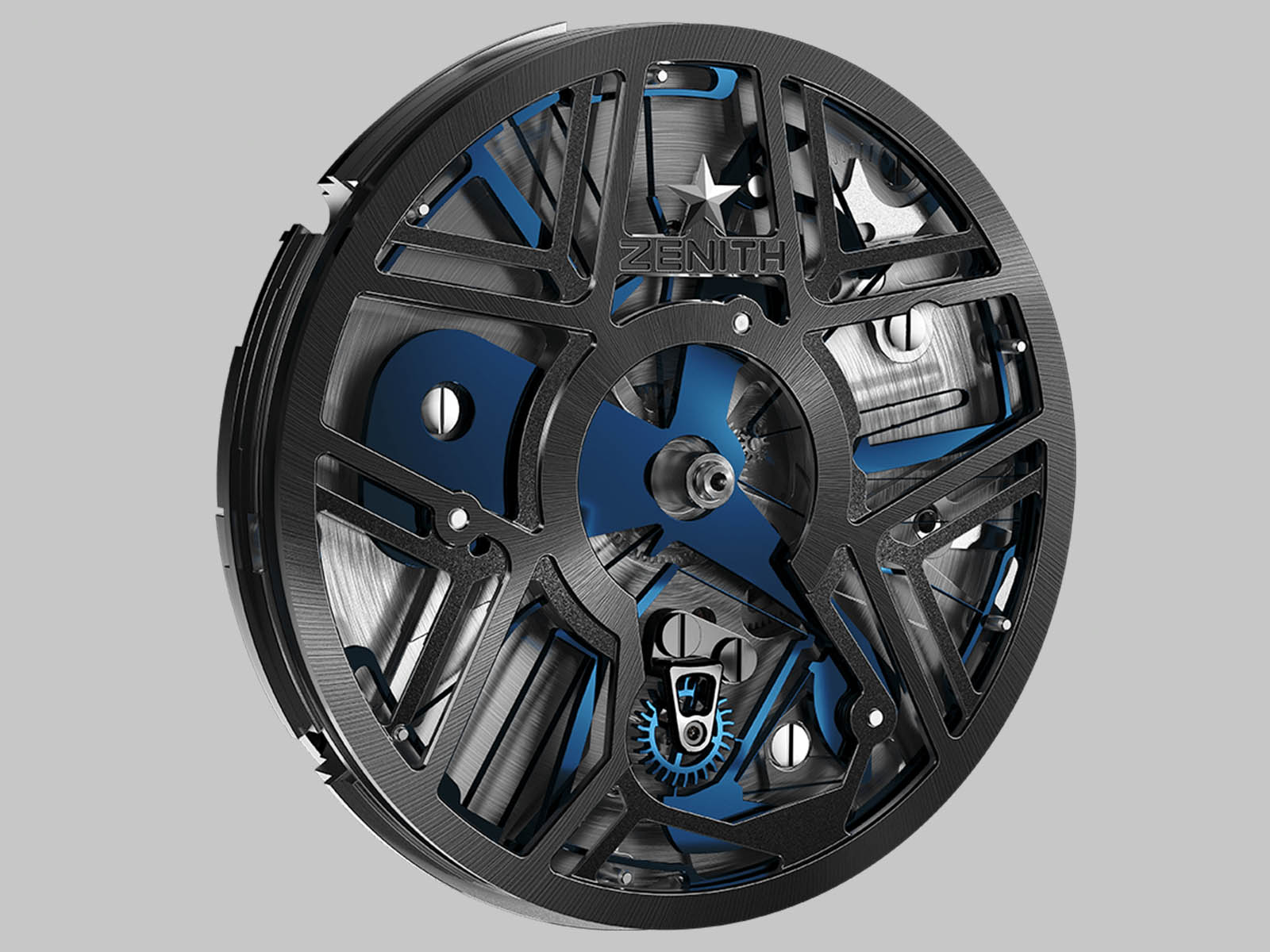

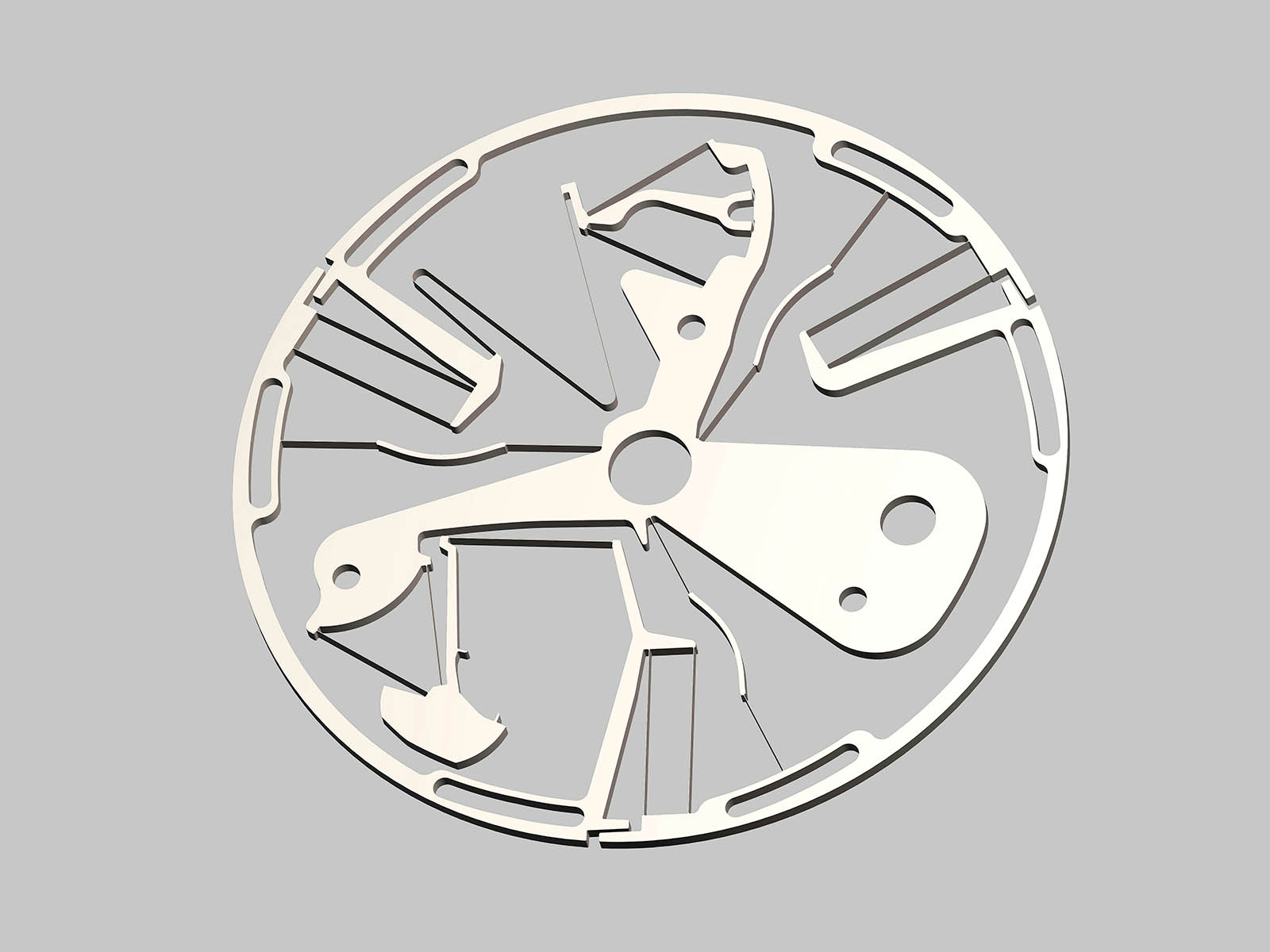

Oscillator

Zenith developed a system called ‘Oscillator’ and used it in the Defy Lab model introduced in 2017. The special watch, which was limited to only 10 pieces, took its place in the collectors’ wrists in a short time by pre-order. However, the brand that which wanted to present the Oscillator system to the industrial platform, succeeded to surprise people who admired not only the watches but also the tradition of watchmaking by releasing the Defy Inventor at Baselworld 2019. The most important feature of the system, which was developed as an alternative to the flexible balance concept used in these models, which is also the backbone of mechanical watchmaking, is that it works with a single component instead of more than 30 pieces that make up the conventional balance. The Oscillator is manufactured from a material called Monocrystalline and operates at a frequency of 18Hz (129.600vph). Reduction of friction/wear rates, precision and accuracy are some of the benefits of this system.